Most people think that colour and flavour are the only two crucial aspects of any food product. But you should know that food texture plays an equally important role. That is why texture profile analysis is used.

The textural characteristics of food items can be divided into two categories: Reaction to stress and derived. These further include:

- Reaction to Stress: Hardness, viscosity, adhesiveness, cohesiveness, and elasticity

- Derived: Brittleness, gumminess, and chewiness

These characteristics can also be divided based on their analysis methods: sensory and instrumental. Sensory texture profile analysis parameters consist of fingers, tongue, teeth, lips, and palate. On the other hand, instrumental analysis is more sensitive and is carried out in strictly defined conditions to gain accurate results.

What Is Texture Profile Analysis of Food?

Texture analysis plays a very important role in sensory evaluation and development of a new food product. It the property of food which is associated with the sense of feel or touch experienced by fingers or the mouth.

Although one may feel the texture while handling, texture indicated best by the sensations caused by contact with hard and soft parts of the mouth. Texture characteristics, according to the general food texture profile parameters, are perceived in three stages of ingestion – initial, masticating and residual. These three stages include:

- Initial: Viscosity, hardness, and brittleness

- Masticatory: Gumminess, adhesiveness, chewiness, viscosity, hardness, and brittleness

- Residual: General mouthfeel and breakdown rate

The food’s sand-like texture, also called grittiness, is detected by the tongue and the upper part of the mouth. The same parts are used for detecting butter’s meatiness and ice creams’ sand defect, which is also found in sweetened condensed milk.

Usually, characteristics like chewiness, gumminess, and hardness are determined by the teeth’s pressure. The thumb ball and fingertips decide the brittleness, stickiness, and sponginess of these items. Finally, the mouthfeel is when oral cavities feel thick and miscible liquid in the mouth.

Subjective evaluation of texture could also be made but its time consuming, requires trained personnel and may not always be useful in the standardization of texture of foods.

Texture testing is a well-established technique for evaluating the mechanical and physical properties of raw ingredients, food structure, and designs, and for pre- and post-quality control checks.

Texture testing has applications across a wide range of food types, including baked goods, cereals, confectionaries, snacks, dairy, fruit, vegetables, gelatin, meat, poultry, fish, pasta, and even pet food.

Since the texture is a property related to the sense of touch, it can be measured easily by mechanical methods in units such as force. In texture testing, standard tests such as compression, tension, and flexure are used to measure hardness, crispiness, crunchiness, softness, springiness, tackiness, and other properties of food.

Comparing the results from mechanical texture analysis with trained human sensory panels has shown that the measurements have a high correlation with the various sensory attributes associated with textural quality.

For natural products such as fruit, vegetables, meat, and fish, textural properties can be traced back to the way the product is grown, or reared, while for processed food, the textural properties can be used to optimize the process.

Texture analysis can highlight quality improvement opportunities throughout the supply chain and the production process. At the research and development stage, new or alternative ingredients can be compared with existing ingredients. In production, texture analysis is used for the measurement and control of process variations such as temperature, humidity, and cooking time.

It can be used to adhesiveness, chewiness, cohesiveness, consistency, crispiness, crunchiness, elasticity, extensibility, firmness, fracturability, gel strength, gumminess, hardness, rupture strength springiness, stiffness, stringiness, texture profile analysis toughness, work to cut, work to penetrate, and work to shear.

General Applications:

It is helpful in developing the food product, different R&D labs, sensory evaluation and support to plants such as milling, baking, and processing of fruits and vegetables and many more….

For example

The huge demand for burgers, together with competitive pricing, means that their composition can vary significantly, from 100% prime ground beef to poor-quality meat containing a high percentage of fat, bulking agents, salt, and other additives. So it can measure the softness of burger

The stickiness of cooked sheets of pasta is related to the starch content of the pasta sheet, which in turn is related to the cooking temperature and time. These parameters can be optimized by measuring pasta stickiness.

Many food products are packaged in a flexible wrap that is required to be tested for its tensile strength, puncture resistance, heat bond peel strength, tearing strength, and coefficient of friction.

Instrumental Texture Profile Analysis

As stated earlier, there are two basic methods of analysing the textural properties of food: sensory and instrumental. While the first one includes the working of sensory organs, the second one is done with different tools. Instrumental texture profile analysis of food can further be classified into distinct groups:

- Fundamental: This part includes measuring the viscosity, elasticity, and other rheological properties of the food item.

- Empirical: This part deals with those texture profile analysis parameters that are not appropriately defined, but they do play a crucial role like the hardness and consistency.

- Imitative: As the name suggests, here the practical food conditions are stimulated to observe its reaction.

In this profile analysis, several instruments are used like Succulometer (to measure moisture content), Tenderometer (to measure tenderness or maturity), Penetrometer (hardness or consistency measurement), and a food texture analyzer (to determine mechanical characteristics). Through these instruments, proper analysis of food texture gets done, and reports can be generated.

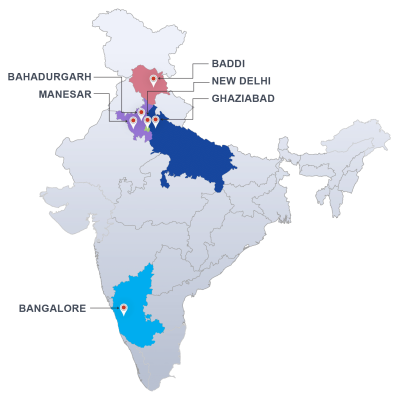

Texture Profile Analysis of Food at Our Lab

We offer a complete texture analysis of your products in our laboratory. Our professionals carry out all tests in a well-maintained structure and conditions so that to obtain a proper analysis of the given sample. With our accurate results, you can further optimize your processes of production to make the food item even better for consumers.

You can reach us through the ‘Quick Query form’ for any queries or opt for our food texture analyser. We are also available on phone: +91-11-45754575. Our experts will be happy to assist you with the process.

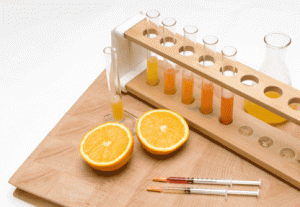

Image courtesy of [antpkr] / FreeDigitalPhotos.net