In today’s day and age, brands are dealing with consumers that aren’t just smart but health and environmentally conscious too.

They are aware of the repercussions of poor packaging on the products they consume and how it impacts the environment and their health at large.

Owing to this awareness, businesses must focus on regular food packaging materials testing to ensure there’s minimal waste or non biodegradable materials used by reducing the net packaging waste and identifying solutions to become more eco-friendly and safer.

The right packaging also needs to ensure the safe delivery of the product through the supply chain.

If you;re a business owner in the food industry, we can help you navigate the world of regulation and compliance for food packaging.

Our food packaging materials testing labs can run the right quality tests to ensure that your food packing is safe and eco-friendly.

Parameters for Testing Food Packing

There are multiple packaging material testing aspects that you must consider while testing food packings like:

- The material should keep the food item safe, hygienic, and fresh representing the food creatively

- The printing shouldn’t fade out due to friction between materials surrounding the food item

- The seal should be leak-proof ensuring that the packet doesn’t burst

- The container used for food packaging shouldn’t puff out or leak

- The material should adhere to the guidelines listed by the FSSAI

Quality control tests for packaging material

The complete testing of packaging materials becomes much easier when adequate measures and appropriate tests are conducted. Here are the major tests conducted for the quality control of packaging materials.

- Edge Crush Test [ECT]

- Bursting Strength Test [BCT]

- Puncture Resistance Test

- Compression Testing

- Food Packaging Seal Integrity Testing

- Reduced Pressure Tests

-

Parameters that the Packaging Material Must Surpass

Here’s a quick overview of the parameters that the packaging material must surpass to be cleared for distribution:

- The packaging material should ensure an adequate barrier to microorganisms.

- The packaging material should be tamper proof, should pass the seal integrity test in a way that it can be sealed only once.

- The size should be ideal for wrapping to avoid gapping & billowing

- In case, the food will directly touch the food packaging material, the food packaging testing laboratory must verify and certify the packaging material being used

- Packaging materials like aluminum, plastic & tin should be tested for physical, microbiological and chemical analysis

- The gases used during packaging should not be toxic and shall not pose any health hazards for the community

- All food materials have to be tested from a food testing laboratory in cases of any suspicion or possible contamination before the food is made available for the sale

Why Arbro Pharmaceuticals for Packaging Testing?

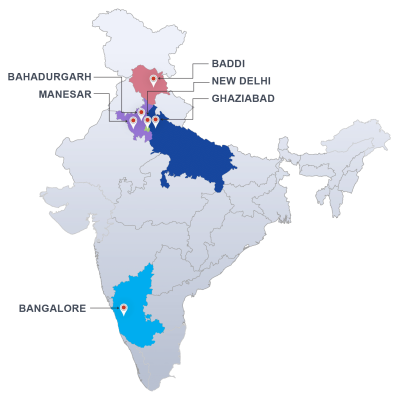

Our food and packaging material testing lab/laboratory and professional team of scientists are experts in testing food packaging materials. We have a comprehensive range of equipments and our testing services include national & international methods for the evaluation of food packaging materials.

Our food testing laboratory has been identified as one of the top 5 laboratories and is accredited by NABL, FSSAI, BIS, CDSCO, ISM&H, APEDA, EIC/EIA, AGMARK.

We offer consultation and testing on the requirements of the package materials as per IS – 9845, IS – 10171, IS – 15392. Our techniques include mechanical testing, chemical testing, microbiology testing, and evaluation of packed materials.

Our other packaging testing services include – Food Microbiology testing, Nutritional & labeling, Allergens, Food Additives, Residues/Chemical Contaminants, Shelf Life Studies, Sensory Evaluation.

Please contact us today using the quick query form on the right or by calling us now on +91-11-45754575 for the testing of food packaging materials.

FAQs

1. How do you test packaging materials?

Under our food packaging material testing, the material has to pass the following parameters:

Quality control of packaging materials

An appropriate size for wrapping

Chemical, physical, and microbiological tests for aluminium, tin, and plastic materials

A proper wall for the microorganisms

Safety, if the food directly touches the packaging

Safety of the used gasses

Food packaging seal integrity testing for tamper-proof

2. Do you conduct food-grade testing for packaging materials?

Yes, in our packaging material testing lab, food-grade testing is conducted on the packaging materials that come directly in contact with the food item. This ensures that no toxicity transfers from the material to the food, and the item remains safe for consumption until it gets delivered.

3. What is food packaging seal integrity testing?

All packaged food consists of a seal that keeps the food item protected inside the packaging. But what if this seal isn’t reliable enough, and it gets broken during the transport or processing? In order to avoid such incidents, food packaging seal integrity testing is carried out along with the testing of packaging materials. It analyses the seal’s strength to ensure that it offers the required protection to the food item.

4. What are the different types of quality control tests for food packaging?

Quality control tests are done to ensure that the used food packaging is safe for both consumers and the environment. A variety of quality control tests for packaging material get conducted for this purpose, such as:

Edge Crush Test (ECT)

Reduced Pressure Test

Compression Testing

Bursting Strength Test (BCT)

Foot Packaging Seal Integrity Testing

Puncture Resistance Test

5. Do you do a migration test?

As the food packaging material can easily transfer its elements to the food, it is crucial to perform migration tests under food packaging testing. It ensures that the migrating substances remain below their Specific Migration Limit (SML) that is determined based on their individual toxicity. Our experts perform the appropriate migration test in our packaging testing lab to check all the required factors.