Ethylene oxide residuals testing is essential when using ehylene oxide for sterilisation of medical devices to ensure that the levels of ethylene oxide (EO), ethylene chlorohydrin (ECH) and ethylene glycol (EG) are controlled and within the limits to avoid any risk to the patient during normal use of the products.

This is a requirement really stated in the international standard document ISO 11135 – 1: 2007. It is essential to test for EO residuals to avoid harmful effects like irritation, mutagenicity, carcinogenicity, organ damage and reproductive side effects.

When it ethylene oxide chosen as a sterilisation agent steps must be taken to minimise the exposure to EO residuals. ISO 10993-1 lays down the biological evaluation and testing requirements for each individually designed medical device. Over and above the requirements of ISO 10993 – 1 it is essential to meet the requirements of ISO 10993 – 7 which lays down the EO sterilisation process residual limits.

Together with the biological evaluation, ethylene oxide residual testing provides the justification that a medical device sterilised using ethylene oxide is safe for human use.

Part seven of ISO 10993 lays down the limits for residual ethylene oxide and ethylene chlorohydrin in individual EO – sterilised medical devices and the procedures for the measurement of EO residue and ECH residue.

Ethylene oxide treatment is one of the most common approaches for sterilisation of medical devices. It is important to develop validate and put in place procedures for routine control of ethylene oxide sterilisation processes and testing the resulting EO residuals in the products.

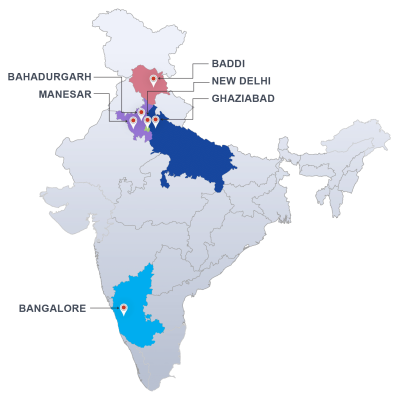

Our testing laboratories located in New Delhi, Baddi, Himachal Pradesh and Bangalore, Karnataka are fully equipped and routinely carry out EO residue testing for the leading manufacturers of medical devices across India.

We have even supported numerous process validation and dose audit studies for establishing successful ethylene oxide sterilisation cycles while minimising the residual levels in the products.

Please feel free to contact us and our team of experts will be happy to get back to you with a proposal for testing your samples for ethylene oxide residuals.