In the pharmaceutical and cosmetics formulations, benzene testing is an important process to ensure the safety of the products. Benzene is a toxic substance that can be present as an impurity in certain pharmaceutical products, such as solvents, reagents, and active pharmaceutical ingredients.

Exposure to benzene can cause serious health problems, including cancer and other diseases. Benzene testing is typically performed throughout the manufacturing process, from raw materials to finished products. In the case of cosmetics, benzene can be found as a contaminant in ingredients such as fragrances, solvents, and colorants. Similarly, in drugs, benzene can be present as an impurity in active pharmaceutical ingredients and excipients.

Benzene found in products of popular brands

- Benzene has been found in consumer products like sunscreen, after-sun care lotions, and hand sanitizers. Popular brands were identified recently as having harmful levels of benzene in their aerosol sunscreens after testing resulting in voluntary recalls. Multiple brands of hand sanitizer have also been identified with levels of benzene beyond 2 ppm described as safe by the FDA, as well as personal care products like spray deodorants.

- There have been many other aerosol personal care products such as dry hair shampoos and conditioners with levels of benzene to cause concern. Benzene testing in cosmetics is an important practice that can help to ensure consumer safety, promote regulatory compliance, enhance brand reputation, enable product improvement, and advance scientific understanding.

Why is Benzene Testing crucial in drugs and cosmetics?

- The testing is often done at different stages of the process to ensure that benzene levels remain within acceptable limits.

- The results of the testing are reviewed by quality control personnel and management to ensure that the products meet the required standards for safety and quality.

- Benzene testing is an important part of the quality control process in the pharmaceutical industry. It helps to ensure that products are safe and effective for use, and that they meet the standards set by regulatory agencies.

- By performing regular benzene testing, pharmaceutical companies can maintain high standards of quality and safety for their products.

What is Benzene?

Benzene is a carcinogenic substance that can be present in trace amounts in certain solvents, reagents, and active pharmaceutical ingredients (APIs) used in the manufacturing process of pharmaceuticals and cosmetics. Therefore, the testing is necessary to ensure that the final product is safe for human consumption.

Benzene testing is performed at different stages of the manufacturing process to ensure that benzene levels are within acceptable limits. The testing is typically conducted on raw materials, intermediates, and final products to detect any impurities. The results of the testing are reviewed by quality control personnel and management to ensure that the products meet the required safety and quality standards. In addition to regulatory requirements, many pharmaceutical companies have their own internal standards for benzene levels. These standards are often more stringent than regulatory requirements to ensure that their products meet the highest safety standards.

Benzene in Pharmaceutical Products

Benzene testing is an essential aspect of quality control in the pharmaceutical industry. It helps to ensure that pharmaceutical products are safe for human consumption and meet regulatory and internal quality standards. By regularly testing for benzene, pharmaceutical companies can maintain high standards of safety and quality in their products.

Benzene in Cosmetic Products and Health Risk

Benzene testing in cosmetics refers to the process of analyzing cosmetic products to detect the presence of benzene, a known human carcinogen. Benzene is a colorless and highly flammable chemical that is widely used in the manufacturing of various products, including cosmetics. In recent years, concerns have been raised about the potential health risks associated with exposure to benzene in cosmetic products. Studies have shown that exposure to benzene can increase the risk of cancer, as well as other health problems such as anemia and damage to the immune system. Benzene testing in cosmetics is an important step in ensuring the safety of cosmetic products and protecting consumers from the potential risks associated with benzene exposure.

Regulatory Aspect

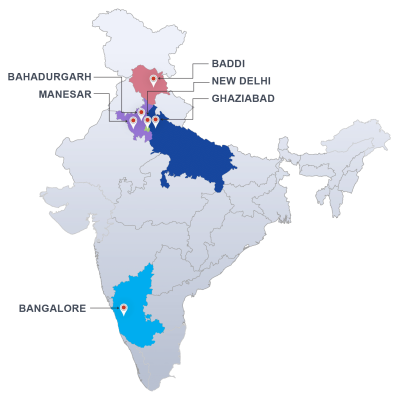

- In India, the regulatory requirements for benzene testing in drugs and cosmetics are established by the Central Drugs Standard Control Organization (CDSCO), which is the regulatory agency responsible for the approval and regulation of drugs and cosmetics in India.

- The CDSCO has established guidelines and standards for benzene testing in drugs and cosmetics, which are based on international standards such as those set by the International Conference on Harmonisation (ICH) and the World Health Organization (WHO).

- According to these guidelines, benzene levels in drugs and cosmetics should be kept below a certain limit, depending on the product and its intended use. For example, in the case of pharmaceuticals, the CDSCO specifies that benzene levels should not exceed 2 parts per million (ppm) in the finished product. Similarly, for cosmetics, the CDSCO specifies that benzene levels should not exceed 1 ppm in the finished product.

- To comply with these regulatory requirements, manufacturers of drugs and cosmetics in India are required to conduct regular testing for benzene and other impurities.

- The testing is typically performed by accredited laboratories, using validated analytical methods and established protocols. The results of the testing must be reported to the CDSCO as part of the product registration process, and manufacturers must demonstrate that their products comply with the regulatory requirements for benzene and other impurities.

- In addition to the CDSCO, other regulatory agencies in India may also have specific requirements for benzene testing in drugs and cosmetics, depending on the product and its intended use. Laboratories conducting benzene testing for drugs and cosmetics in India must therefore stay up-to-date with the latest regulatory requirements and ensure that their testing methods and protocols comply with these requirements.

- Manufacturers of cosmetic products in India are required to comply with these regulatory requirements and standards. Failure to comply with these regulations can result in legal and financial penalties, including product recalls, fines, and damage to brand reputation.

- To protect consumers from the potential harm of benzene exposure, regulatory agencies around the world, including the US FDA, have established limits on the amount of benzene that is allowed in cosmetic products.

Methods used in our laboratories for cosmetics and Drugs

There are several methods of benzene testing used in the pharmaceutical industry, including gas chromatography (GC), high-performance liquid chromatography (HPLC), and mass spectrometry. These methods can detect and measure benzene levels in pharmaceuticals and materials throughout the manufacturing process, from raw materials to finished products.

Gas Chromatography-Mass Spectrometry (GC-MS):

It involves separating the different components of the cosmetic product through gas chromatography and then analyzing the resulting components using mass spectrometry. This technique can detect benzene at very low concentrations.

Headspace Gas Chromatography (HS-GC):

HS-GC is a technique that is used to analyze volatile organic compounds, such as benzene, in cosmetic products. This method involves extracting the volatile compounds from the sample using a headspace sampler and then analyzing them using gas chromatography.

Liquid Chromatography-Mass Spectrometry (LC-MS):

LC-MS is another common method for benzene testing in cosmetics. It involves separating the different components of the cosmetic product through liquid chromatography and then analyzing the resulting components using mass spectrometry.

Fourier Transform Infrared Spectroscopy (FTIR):

FTIR is a technique that is used to identify and quantify different chemical compounds in a sample, including benzene. It involves measuring the absorption of infrared light by the sample and comparing it to a reference spectrum.

Advantages of Benzene Testing

- Ensures consumer safety: The primary benefit of benzene testing in cosmetics is that it helps to ensure consumer safety. Benzene is a known human carcinogen, and exposure to it through cosmetic products can be harmful to human health. By testing cosmetics for benzene, manufacturers can identify any potentially harmful levels and take action to ensure that the product is safe for use.

- Promotes regulatory compliance: In many countries, including the US and EU, there are limits on the amount of benzene that is allowed in cosmetic products. By testing their products for benzene, manufacturers can ensure that they comply with these regulations and avoid potential legal and financial penalties.

- Enhances brand reputation: By demonstrating a commitment to product safety and regulatory compliance, companies can enhance their brand reputation and build trust with consumers. This can lead to increased customer loyalty, higher sales, and improved brand perception.

- Enables product improvement: By identifying any sources of benzene contamination in their products, manufacturers can take steps to improve their manufacturing processes and prevent future contamination. This can lead to higher-quality products and improved customer satisfaction.

- Advanced scientific understanding: By testing cosmetic products for benzene and other harmful substances, scientists can gain a better understanding of the health risks associated with exposure to these chemicals. This knowledge can inform future regulations and help to protect public health.

What WHO says?

- Benzene is known to cause cancer in humans according to the World Health Organization (WHO), the International Agency for Research on Cancer (IARC) and the U.S. Centers for Disease Control and Prevention (CDC).

- Numerous studies have confirmed that exposure to benzene whether through inhalation, skin absorption, ingestion, skin or eye contact poses significant health hazards. Benzene contamination in sunscreens and after-sun products is a serious public health concern since they are regularly used by adults and children of all ages to prevent sunburn and skin cancer.

Is Benzene Dangerous?

Benzene is a known carcinogen that can cause significant damage to humans. Overexposure to benzene can result in cancer, a reduced red blood cell count, anemia, immune system damage, and excessive bleeding. Benzene is dangerous, and thus exposure should be avoided whenever possible. The FDA’s legal limit of benzene is two parts per million (or 0.0002%).

Benzene Testing in Cosmetics and Drugs in our labs

We ensure that your product is of high quality, safe for end-users, and compliant with health and safety regulations. We use validated methods approved by FDA to detect benzene in cosmetics and pharmaceutical products. Our team can also work with you to review your product’s formulation to ensure it is safe and compliant. We use sophisticated technology to find trace impurities in consumer and industrial products to avoid any hurdle in smooth functioning of your business. We reduce the risk by identifying sources of contaminants and implementing quality measures to keep the levels of these contaminants below regulatory and toxicity thresholds.

For any query you can Contact us or fill out our Query form, call us now on +91-8588851888 or drop an e-mail to [email protected]. We will be happy to provide you with a proposal for your testing requirements.