In recent year’s drug discovery and development has been producing compounds of increasing potency, they show their pharmacological effects at very low doses. These extremely potent substances are very hazardous, drugs like steroids, hormones, anti-cancer drugs, as well as drugs like beta-lactam and cephalosporins, which are known to produce allergic reactions in susceptible populations can cause serious adverse events at very low levels.

To protect the patients from the occurrence of such adverse events, it is very important that their manufacturing operations are properly isolated to avoid cross-contamination in other pharmaceutical products being manufactured in the same or adjoining facilities.

All pharmaceutical companies are now using state-of-the-art containment systems and even establishing dedicated manufacturing facilities for such products. Despite the best of their efforts, cross-contamination can still occur through the movement of staff, documents, materials, and failure of air handling systems.

Regulatory bodies are taking an increasingly critical view of this aspect of manufacturing operations and controls. Besides the proper qualification and regular monitoring of the performance of containment systems, they are also demanding that there must be in place a stringent containment monitoring program to establish documented evidence, based on sound scientific principles, that no cross-contamination is occurring between the different manufacturing blocks located on the same campus.

A number of leading pharmaceutical manufacturers around the world have received nonconformities and 483s during the audit of their facilities on this aspect, due to the absence of a proper containment monitoring program.

The acceptable approach towards containment monitoring is to carry out regular air sampling and swab sample analysis for detection and quantification of trace levels off the potent drugs in the adjoining areas and general manufacturing blocks.

It is recommended that sampling and analysis using validated methods should be carried out every month for at least three months, then every three months for the first year, then every six months for the second year and subsequently at least once every year, to establish the effectiveness of the containment procedures used in the facility.

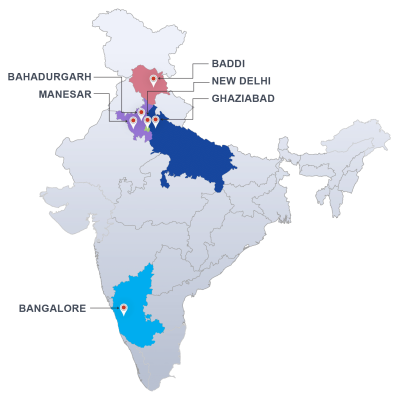

We had Arbro has been supporting numerous clients for their containment monitoring programs. We have established and validated analytical procedures for quantifying numerous beta-lactam, cephalosporin, and other potent drugs at ultra-trace levels in slab and air samples using LCMSMS.

We also carry out on-site swab sampling and air sampling using established and validated sampling procedures as part of your containment monitoring program.

Contact us today to get a proposal for containment monitoring of your facility using the quick query form on the right or call us now on +91-11-45754575.

2 Responses

It is recommended that sampling and analysis using validated methods should be carried out every month for at least three months, then every three months for the first year, then every six months for the second year and subsequently at least once every year, to establish the effectiveness of the containment procedures used in the facility.

please confirm the above mention frequency required for containment study

Dear Arnab, You are correct. This is what most people are following.