Do you know that your hospital, manufacturing unit, pharmaceutical, petrochemical, medical, food and beverage industry requires a periodic compressed air testing service? It is important for plant operators to monitor the quality of compressed air in their processes. If you get the compressed air quality tested you can save unnecessary hurdles in the smooth functioning of your business.

Compressed air quality testing ensures that the air supplied to industrial processes is free of impurities that might damage the equipment or alter the quality of finished products.

Why is compressed air testing required?

A compressed air testing will ensure that the compressed air being supplied to industries should be routinely tested to ensure that it is free of impurities.

The contaminants which are water, suspended particles, and oil residue are generated from three major sources:

- Contamination from ambient air drawn into the compression system

- Impurities introduced from compressor parts and lubrication oils

- Inbuilt contaminants from piping and storage components of air compressors

Importance of compressed air quality testing

Compressed air testing is crucial in large industrial set up where high quality products are manufactured. The impurities in air quality could damage the costly equipment and final products. This is why it is crucial to follow the guideline of WHO and Factory act during all process cycles which requires compressed air usage.

Method used for sampling and analysis

The ISO 8537 compressed air standard is an internationally recognized system that applies to the purity of compressed air in an industrial setting. This testing protocol is both an efficient and cost-effective method of determining the level of impurity present in a pressurized gas sample.

Compressed air ISO 8573 testing schedules for particulate contaminants, water, and oil.

Parameter, test method and standard limits

Dew point ISO 8573 (P-03)-1999 should be less than 94 degree Fahrenheit

Oil Aerosol content mg m3 –ISO 8573 (P-02) -2001 should be less than 0.01mg/m3.

Relative humidity, % ISO 8573 (P-03 )-1999

Microbiological test

Total Bacterial Count cfu plate –ISO 8573 (P-07)-2003- 500

Yeast and mould cfu plate / ISO 8573 (P-07)-2003- 200

Industries we serve

Hospitals

Manufacturing unit

Pharmaceuticals

Medical

Food and beverage

Power plants

Hotels

Construction sites

Petroleum plants

Sugar industry

Distilleries

Major equipment used for compressed air quality testing

We collect the sample through a sampler at an outlet or compressor. Few parameters are analysed through digital sensors and few in the laboratory.

Our services

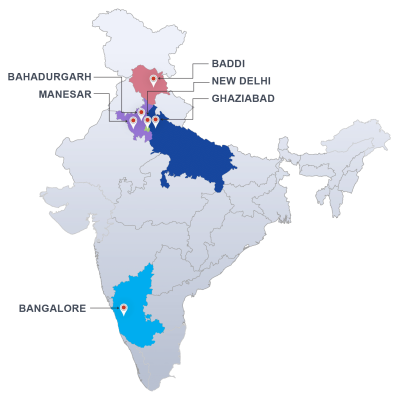

We offer compressed air testing services in our labs in PAN India locations. We are equipped with most avant garde laboratory instruments which enable us to provide a vast array of environmental services. The State-of-the-art infrastructure available helps in carrying out analysis of chemical and microbiological parameters.

If you would like to use our testing services please feel free to contact us through the contact form or call us now on +91-11-45754575. We will be happy to provide you a proposal for Compressed Air Testing etc.