Solid State Characterization is a crucial aspect in the development of pharmaceuticals as drug products are mostly produced as solid materials and it is highly significant for the pharmaceutical industry. Even a slight change in structure or particle size of a drug product can affect Pharmacological behavior of a drug. This is why in order to develop safe and efficient drug products it is important to study Active Pharmaceutical Ingredients (API) and excipient particle size right from the drug development to manufacturing.

The need to investigate the solid-state properties of API has become important in the pharmaceutical development industry. Physical properties can vary widely between batches, leading to batch-to-batch variability.

The most critical aspect of pharmaceutical compounds development is selection of the optimum solid form as they have the ability to exist in more than one form or crystal structure (polymorphism). These polymorphs show different physical properties which can affect their biopharmaceutical properties.

Solid state characterization of pharmaceuticals, determines physical properties such as particle size, polymorph and morphology of solid dose drug forms. It is a vital key to understand the physical properties of pharmaceutical solid materials and ensure optimal physical form. Significantly, these physical properties can have an impact on the material’s bulk properties, drug formulation performance, process, stability and appearance.

Primarily, Solid state characterization is used to measure properties of solid materials. Usually, characterization is done by measuring the material’s response to external forces.

Method to Analyse Structural Changes

In order to allow the external force to get into the material, apertures are made on the surface of the material. Then the sample is heated while ensuring that the material does not break apart. Once the temperature is reached, the material is allowed to cool down again. The change in temperature causes the molecules inside the material to move around. When this occurs, the internal structure changes. Some of the most common methods to measure changes in structure include infrared spectroscopy, X-Ray Diffraction, Differential Scanning Calorimetry, Thermogravimetric Analysis, and Microcalorimetry.

Significance of Solid-State Characterisation in Pharmaceutical Products

- The functional behavior, dissolution, bio-availability of any pharmaceutical product depends on DSC, HRD, and microscopy. It is important to control and analyse the solid-state characterization of the API in cases of excipients also.

- In crystal there can be different crystalline forms either polymers special arrangement of molecules which can lead to differences in lipid behavior like compression behavior so in order to characterize it we use technique like DSC which can become difference in the melting point or if there is an absence of melting point which can show that it is an amorphous system it can also be thermal stability of amorphous systems

Why choose us?

- Our highly skilled scientists can undertake studies that range from routine to highly complex and challenging characterization.

- We ensure our testing services are compliant with current regulatory requirements.

- Our State-of-the-art equipment supports development, stability and batch release in fast turnaround time.

- Our lab is equipped with XRD which plays an important role in the development of new drugs, as it helps to characterize active materials as well as tests material at different stages of manufacturing so that quality control is effectively maintained. All these procedures help to improve the formulation, analyze the compatibility of excipients, detect bioavailability and improve on factors of stability in different environments.The crystal morphology of the samples can be thoroughly analyzed and monitored with the help of the XRD Detector.

Our Services

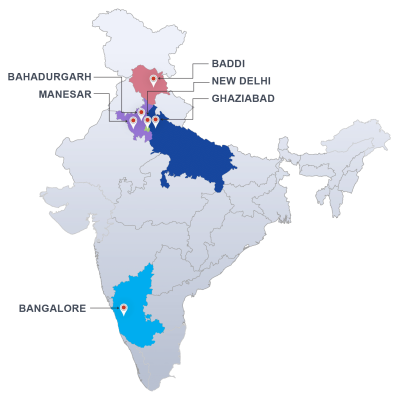

Our team of experts provide a vast range of services to support pharmaceutical product development. Right from the drug formulation, quality control, or GMP and GLP compliant programmes, we make sure that the entire process runs smoothly. Our laboratories in Pan India locations fulfills all the regulatory parameters and is equipped to perform chemical and physical characterization of API and Drug Product during all phases of the drug development process.

Our services and experience will help you to enhance your solid dose pharmaceutical product while ensuring quality and safety. We help you meet all your regulatory requirements through our expertise in Total Quality Assurance.

XRD is used to identify and understand the crystal structure and special arrangement of molecules.

We provide all the services which can help in identification and characterization of solid polymorphic forms , solvents , amorphous and crystalline systems and even conversion of one polymorphic form into another during the formulation process.

As a leading testing, inspection, verification and certification organisation, we offer you extensive experience in particle analysis, delivering an accurate and cost-effective service to help you develop a safe and reliable biopharmaceutical product.

Over the years we have worked with most of the leading companies in this field in India and supported their operations within India and around the world.

Contact us today to get a customised solution for your requirements. You can use the quick query form on the right or call us now at +91-11-45754575.