Do you know that stack emission monitoring for your manufacturing facility, hotel, hospital and plant is important to fulfil the regulatory needs and ensure safety of the environment and living beings? The pollutants emitted from the stack can be solid, gaseous, liquid organic or inorganic. Our stack emission monitoring service can help you to comply with regulations and emissions permits.

A glance at stack

Stack is a chimney which is used to disperse the hot air at a height, emissions & particulate matters that are emitted from the various types of stacks like boiler, flue gas etc. At these heights, the polluted air disperses in a very large area so that concentrations at the grounds are within permissible limits and not harmful for humans, animals and vegetation.

CPCB guidelines for Stack Height

The stack height of Chimney, Boiler, DG set, DG exhaust pipe etc is crucial to determine the dispersion of pollutants in the upper level of air relevant to local building height.

Need for stack emission testing

- The accurate emission data gathered from the test results of stack emission and regulatory compliance adds to the authenticity and reliability of your industry.

- Stack emission testing ensures that the industry is compliant with regulated emission limits in your permit.

- To meet the environmental standard.

- Collect data for Emission records.

- For the process of Calibration of continuous emission monitors (CEMs)

- To change or install pollution control equipment.

Accreditations and regulatory requirements

We are ISO 11255 accredited for most stack emission measurement requirements which include monitoring of particulates, heavy metals such as Mercury, N2O, CO, CO2, O2, SO2, TOC, dust, flow, pressure, temperature and moisture.

Stack Emission Monitoring & Testing method

The industrial stack monitoring requires accurate measurement of Pressure, moisture, humidity, gases, velocity, temperature and Particulate matter. We use gas chromatography and Flame Ionization Detection (FID), a reference method technique to measure total hydrocarbons (THC, VOC, TOC), besides chemical parameters and spectrophotometry is used for monitoring toxic gases.

Limit of Particulate Matter Emission for Stack Monitoring

As per CPCB or Indian standards for Industrial Stack Monitoring the flue gas emission from boiler stack, DG set emissions, the furnaces should not exceed the limit for Particulate matter beyond 150 mg/Nm3. However, this limit can vary depending on the industry type.

Turnaround time

The sampling duration of stack gases and source emission is 2 hours and analysis takes 3-4 days.

Our stack emission monitoring and testing services

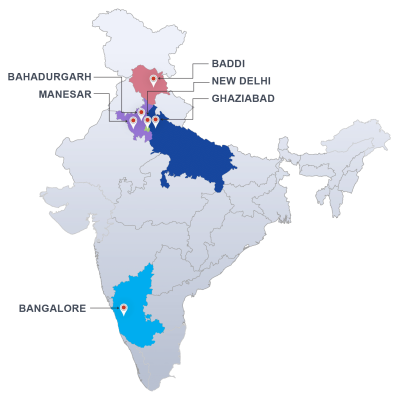

We offer Stack emission testing and monitoring services to keep a check on industrial waste streams that are released into the atmosphere. Our accredited laboratories in pan India locations have been offering Testing and Analysis in the field of Environment. We are equipped with most modern laboratory instruments which enable us to provide a vast array of environmental services. The State-of-the-art infrastructure available helps in carrying out analysis of parameters covering various fields like Water, Waste-water, Ambient air, Stack, Soil, Noise, etc. We carry out various tests to determine pollutants concentrations, emission rate or parameters in the Gas Boiler emission monitoring process.

If you would like to use our testing services please feel free to contact us through the contact form or call us now on +91-11-45754575. We will be happy to provide you a proposal for stack gases and source emission testing services etc.