Milk is a perishable item. When raw milk is kept for a long time at room temperature, visible changes occur. It gets easily spoiled at room temperature.

The taste and quality of milk may deteriorate over time. Hence aspects of milk such as the shelf life, quality etc. must be gauged using adequate tests to ensure that the milk and milk products are not spoiled in the storage, distribution stage.

The shelf life of milk means the time for which milk can be kept without spoilage. Shelf life is important for the dairy industry as it dictates how quickly the supply chain must enable the shipment of the stock from the factory to the table. Stability of milk and milk products mainly depends on different factors like proteins, pH, and ionic calcium.

Here are a few of the major tests that are performed to check the stability and quality of milk.

Rapid Platform Testing:

Rapid Platform testing is very useful in the dairy industry. With a platform test, you can check the quality of milk. On the basis of the result, you can accept or reject the milk sample. If you are a dairy player, you must perform these tests.

Here are two types of Rapid platform tests on the basis of which milk quality is gauged.

Clot On Boiling Test: Clot On Boiling (COB) Test is done to check the heat stability of milk during processing.

Alcohol Test: This test is done to check the heat stability of milk proteins.

Why is a Milk Stability Test necessary?

Milk with low heat stability causes sedimentation during processing. That’s why various treatments are done before and during processing. It reduces the risk of milk spoilage.

Microorganisms produce spores and enzymes which may lead to milk spoilage. Various treatments are done to increase the stability of milk. By application of heat, spore-resistant microorganisms are destroyed. Pasteurization and Ultra Heat Treatment are conducted during milk processing for increasing the stability of milk.

The main cause of milk spoilage is contamination due to microorganisms. If you are in the milk business, you must reduce the chance of contamination to maintain its nutritional quality. Heat treatment is the best way to reduce this risk. Two main heat treatments are pasteurization and UHT.

In pasteurization, milk is heated to at least 630C and followed by holding at such temperature for at least 30 mins or heating at least 720C and holding at such temperature for at least 15 sec.

In UHT (Ultra Heat Treatment), milk is heated above 1350 C for 102 secs. This treatment kills spores.

The stability of milk can be increased in the following ways –

Forewarning: Milk is held at high temperature for a long time. This improves the stability of milk during milk processing.

Addition of Stabilizers: Chemical stabilizers are added to increase the stability of milk. Calcium chloride, citrate, and phosphate are added to milk.

If you are a part of the dairy industry, you must carry these treatments to eliminate the risk of milk spoilage. If the shelf life of milk is increased, it can reach to more far-off places.

Milk Testing and Quality Control

Milk tests help dairy farms to test and assess the quality of milk before it is distributed for processing and ultimately consumption. The product should be free of debris, detergents, coagulations, it should be free of any artificial flavour, it should have a low microbe count, should not be acidic and should not have any foul odour.

For milk to be called pure, it has to clear all these standardized milk tests. If any of these properties will not meet the standard prescribed values, it could cause health issues to the consumers.

Over 6 billion people consume milk and milk products and it is essential for dairy plants to ensure that they conduct regular milk analysis tests to ensure that the product is safe for daily consumption.

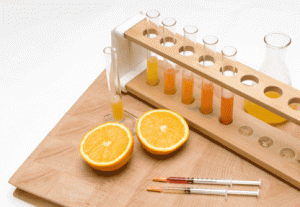

Milk Testing Methods Explained

The common milk testing procedures are Organoleptic tests, Coagulation test (heat stability of milk) and Gerber test.

Organoleptic Tests: The organoleptic test is one of the fastest and cheapest tests to check the quality of the milk. In this method of milk quality control, the person inspecting the produce relies on his sense of taste and smell to judge the quality of the milk.

The milk under inspection is checked for irregularities in colour and appearance. Then, it is smelled/tasted for any odour or sour taste. The packaging of the container is also inspected to understand the hygiene conditions of the area of production. This test is not very accurate and for a deeper analysis of the milk, the sample should be sent to a laboratory.

With this test, inspectors are able to:

Identify the odour of the milk

- Guestimate if the milk the too acidic

- Guess if the cow that produced the milk is in its late lactation phase

- Check for the chemical presence or any discolouration

Heat Stability Test: The heat stability test or the Coagulant test or the Clot on Boiling test is used to determine if the sample that is being tested is too acidic or is high in microorganism count, or has abnormal levels of cholesterol milk.

To conduct the test, take a spoon full of milk or fill required quantities of milk in a test tube or any appropriate testing apparatus and expose it to heat. If the milk clots, it is not fit for consumption and must be immediately rejected. This batch of milk will not be able to withstand the heat conditions at the processing plant.

Gerber Butterfat Test: The Gerber Butterfat test is used to identify the levels of butterfat in the milk sample. The higher level of butterfat, the higher the price of milk. Butterfat is an essential element in making dairy products. To analyse the butterfat content in the sample, one should use the Gerber Butterfat test as a preferred milk testing method.

However, before conducting the Gerber Butterfat test, it is essential to study and understand the breed and pedigree of the producing cow.

To conclude the positive results from the Gerber Butterfat test, the inspected batch of milk should be free from solid coagulants, debris, and discolouration. The fat produced should be crisp and sharply aligned and the fat should be separated by a layer of clear water under it. It should also be in the graduation range.

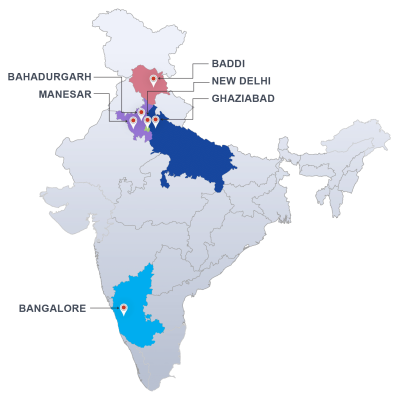

We offer various milk tests at our laboratories in Delhi and Bangalore. We work with reputed clients from the dairy industry. We can help you improve the shelf life of your products. You can contact us at +91-8588851888.